Built to Exacting Standards

Built to Exacting Standards

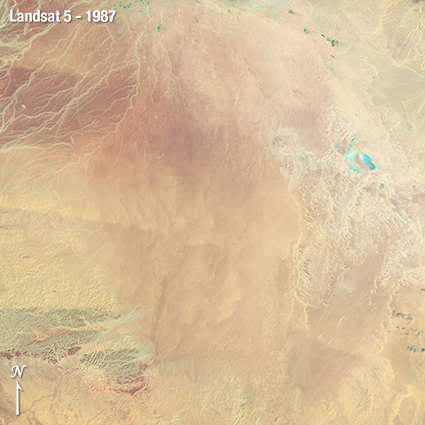

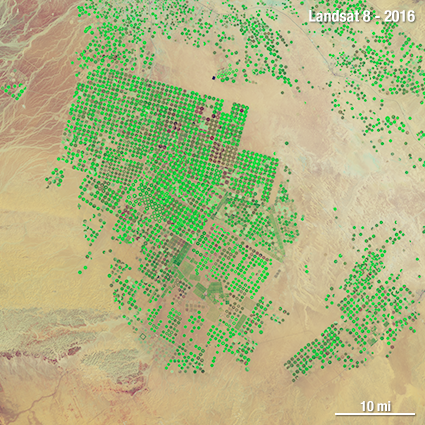

The great strength of the Landsat program is its long data record that provides the ability to look at our planet over the past ~50 years and see what changes man and nature have wrought.

Some change is visually staggering such as large tracks of deforestation or center-pivot irrigation fields appearing in a desert—and new fleets of commercial microsats are able to observe these changes in more temporal detail. Often change is more subtle, like the thermal differences in irrigated fields that tell us about water use or the progressive effects of an insect infestation on a forest. Longer wavelength measurements are needed along with visible and near infrared (VNIR) measurements to see subtle change.

To find incremental changes over time, Landsat data, in all wavelengths from all generations of its sensors, must be intercomparable. This requires accurate calibration and validation (“Cal/Val”) of all of the Landsat sensors.

A team of engineers and scientists closely monitors Landsat sensor behavior over time to ensure that the data collected is comparable spectrally (or radiometrically) and geometrically, for all Landsat sensors old and new. As Landsat 9 was being built, the Cal/Val team made sure the instruments met their set specifications, characterized instrument noise, validated the instruments’ scale with National Institute of Standards and Technology (NIST) benchmarks, and developed any needed correction algorithms.

Ready to Ride: Getting a Science-Grade Instrument into Orbit

Ready to Ride: Getting a Science-Grade Instrument into Orbit

Once Landsat 9’s science-grade instruments were built and tested they were shipped to the spacecraft manufacturer, Northrop Grumman, who mounted the instruments onto the spacecraft bus in a process known as integration. Each instrument went through pre- and post-ship testing before integration began. Once the instruments were mounted on the satellite, environmental testing began. Environmental testing uses a thermal vacuum chamber to simulate the satellite’s expected outer space environment. The satellite went through several cycles of extreme hot and cold temperatures to test its performance in space-like conditions, where the sun appears and vanishes from its view multiple times a day. The satellite was also subjected to acoustic, vibration, and electromagnetic interference tests to ensure the spacecraft could survive its rocket ride into space. Exposing a science-grade instrument to the harshness of space and extreme shaking of blast-off takes lots of forethought.

On-Orbit Check Out

On-Orbit Check Out

Like a massive seafaring ship, a satellite is not ready for active service until a commissioning process takes place. You don’t launch a science satellite on a Monday and get scientific-grade data back on Tuesday. For Landsat 9 an approximately 100-day commissioning, or on-orbit checkout period, is currently underway, after which Landsat 9 will be declared operational. The commissioning process is a highly coordinated effort that proceeds at a swift pace involving over a hundred people directly and hundreds more tangentially. The major players during on-orbit checkout are the Mission Operations Team, the Ground Systems Team, and the Calibration and Validation Teams. These teams are closely coordinating to make sure the spacecraft and instruments are operating correctly and that measurements made by Landsat 9’s two science instruments are accurate and successfully transmitted back to the ground, processed, and made readily available to the public.

Getting Data to You: The Ground System

Getting Data to You: The Ground System

The U.S. Geological Survey is responsible for the Landsat 9 Ground System. The ground system includes all of the ground-based assets needed to operate the Landsat 9 observatory including the satellite command and control center, receiving stations, and data processing and archiving infrastructure—it is a sizeable logistical job to deal with the massive quantity of data that modern Landsat satellites transmit to the ground and quickly get all of that data scientifically-validated and online for anyone on the planet to freely download.